The Lightweight Powerhouse Transforming Modern Engineering

Introduction

Carbon fiber, once a niche material reserved for aerospace and high-performance racing, has steadily evolved into one of the most transformative materials in modern engineering. Known for its exceptional strength-to-weight ratio, rigidity, and design flexibility, carbon fiber is being adopted across industries—from automotive and sports equipment to architecture and renewable energy.

In this article, we’ll dive into the origins of carbon fiber, its manufacturing process, key properties, applications, challenges, and what the future holds for this “black gold” of the materials world.

1. What Is Carbon Fiber?

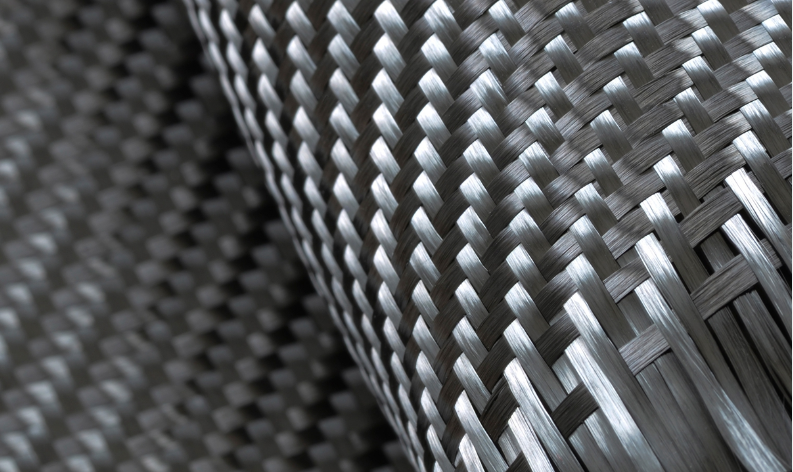

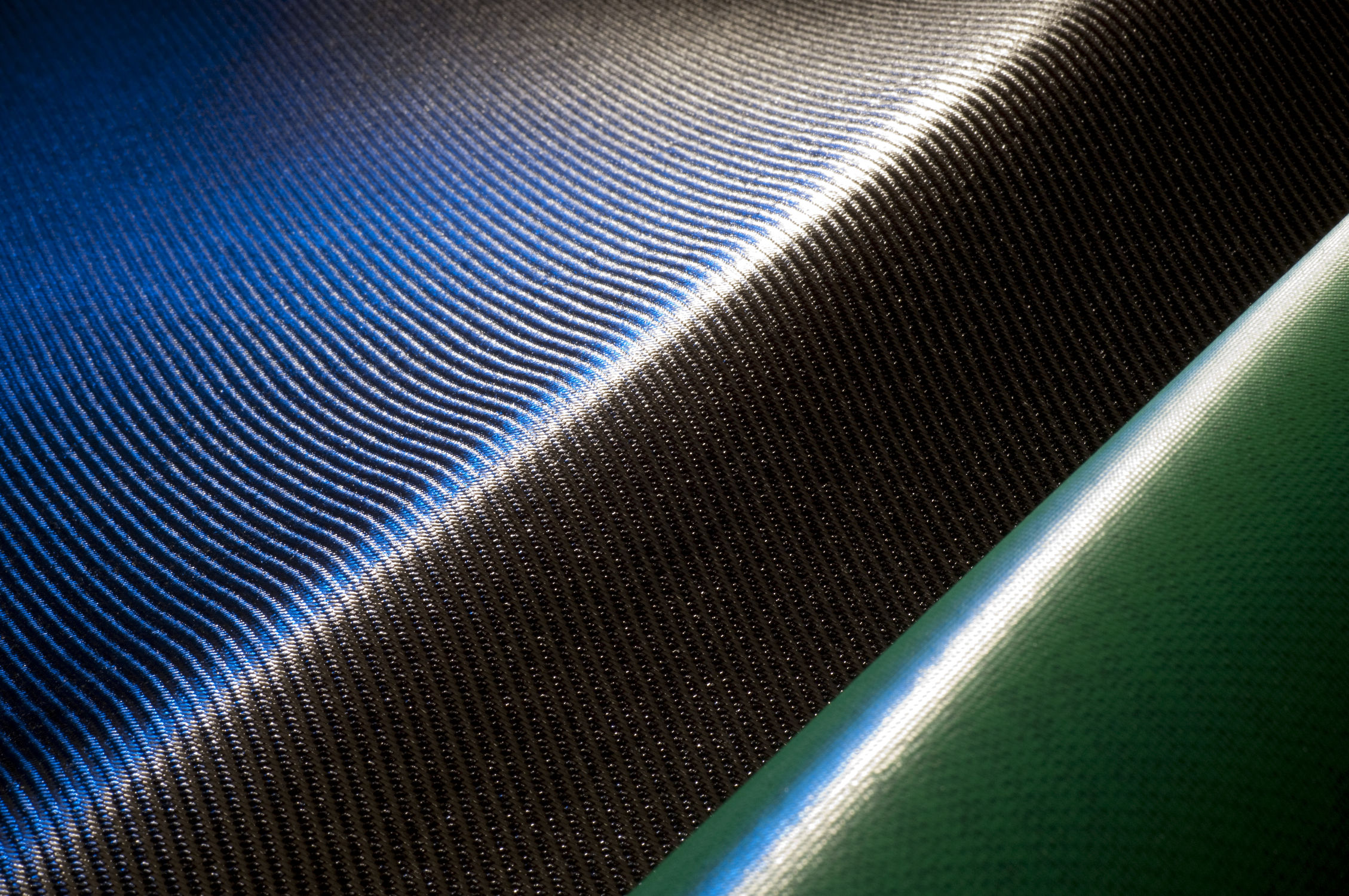

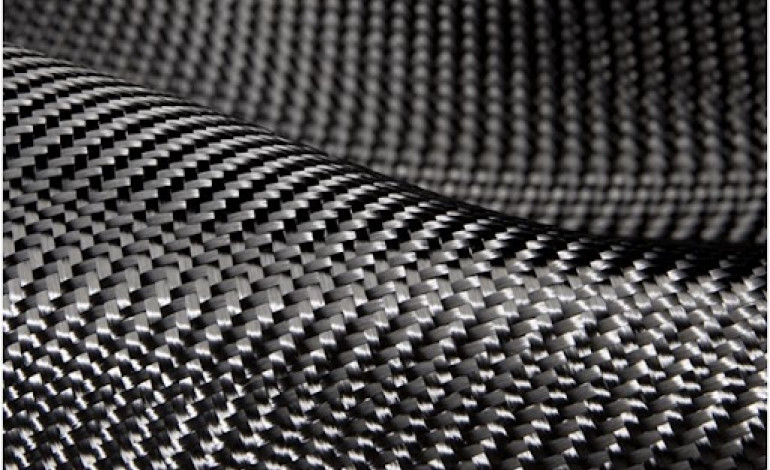

Carbon fiber is a synthetic material composed almost entirely of carbon atoms bonded in a crystalline structure. This arrangement gives the fibers an extraordinary level of strength and stiffness, all while being significantly lighter than traditional materials like steel or aluminum.

Each fiber is typically 5–10 microns in diameter, which is about one-tenth the thickness of a human hair. These fibers are bundled together and woven into fabrics or combined with resins to form carbon fiber reinforced polymers (CFRPs)—the most common form used in commercial applications.

2. A Brief History of Carbon Fiber

Although Thomas Edison used carbonized bamboo and cotton thread in his 1879 lightbulb filaments—essentially early forms of carbon fiber—it wasn’t until the mid-20th century that true carbon fiber as we know it emerged.

-

1958 – The first high-strength carbon fiber was developed by Dr. Roger Bacon at Union Carbide in the U.S., using a rayon-based process.

-

1960s – The British Royal Aircraft Establishment created a more efficient version using polyacrylonitrile (PAN), which remains the most common precursor material today.

-

1970s–1980s – Aerospace and defense industries begin widespread adoption, followed by motorsports and high-end sporting goods.

-

2000s–Present – Mass production techniques improve, and carbon fiber begins to enter consumer markets and infrastructure projects.

3. How Is Carbon Fiber Made?

Producing carbon fiber is a complex and energy-intensive process that involves the following key steps:

Step 1: Spinning

The precursor material—usually PAN—is spun into long strands or fibers.

Step 2: Stabilization

The fibers are chemically altered by heating them in air to around 200–300°C, helping to stabilize the bonding structure.

Step 3: Carbonization

In an oxygen-free furnace, the stabilized fibers are heated to 1000–3000°C. This drives off non-carbon atoms, leaving behind long chains of carbon atoms arranged in a crystalline pattern.

Step 4: Surface Treatment

To improve bonding with resins, the fiber surface is oxidized or etched to increase roughness.

Step 5: Sizing

A protective coating is applied to prevent damage during handling and improve compatibility with resins.

The resulting raw carbon fiber is then woven into sheets or mats, or chopped into short fibers depending on the application.

4. Key Properties of Carbon Fiber

Carbon fiber’s allure comes from a unique combination of mechanical, thermal, and chemical properties:

| Property | Typical Value |

|---|---|

| Tensile Strength | 3.5–7.0 GPa |

| Young’s Modulus (Stiffness) | 230–600 GPa |

| Density | 1.6–1.9 g/cm³ |

| Thermal Conductivity | Moderate (varies by type) |

| Corrosion Resistance | Excellent |

| Electrical Conductivity | High |

Compared to steel:

-

Carbon fiber is up to 5x stronger

-

1/4 the weight

-

2–10x the cost

5. Applications Across Industries

Aerospace

The aerospace industry was the earliest and remains the largest adopter of carbon fiber. Aircraft components—wings, fuselage panels, tail assemblies—use CFRP to reduce weight, fuel consumption, and maintenance.

Example: Boeing 787 Dreamliner is made up of ~50% carbon fiber composites by weight.

Automotive

Luxury and performance vehicles—like McLaren, Ferrari, and Tesla—utilize carbon fiber for structural parts, hoods, roofs, and interiors. Even some mass-market brands are beginning to integrate CFRP to meet fuel efficiency and emissions standards.

Benefits:

-

Faster acceleration due to lower weight

-

Better handling and crash energy absorption

-

Higher fuel economy

Sports Equipment

Carbon fiber is ubiquitous in elite sporting goods:

-

Tennis rackets

-

Golf clubs

-

Bicycle frames

-

Snowboards

-

Fishing rods

Its combination of stiffness and low weight enhances performance, especially in competitive sports.

Construction and Architecture

Though less common due to cost, carbon fiber is used for:

-

Earthquake-resistant reinforcement of bridges and buildings

-

Lightweight prefab elements

-

High-performance cladding and facades

Wind Energy

Modern wind turbine blades—often exceeding 80 meters in length—use carbon fiber for key structural areas to reduce weight while maintaining rigidity.

Medical Devices

Prosthetic limbs, surgical instruments, and diagnostic equipment benefit from carbon fiber’s biocompatibility and radiolucency (invisible on X-rays).

6. Challenges & Limitations

Despite its many strengths, carbon fiber is not without challenges:

High Cost

Producing carbon fiber is energy-intensive and complex. Prices range from $10 to $50 per pound, compared to steel at less than $1 per pound.

Brittle Failure

Unlike metals that deform before breaking, carbon fiber tends to fail suddenly and catastrophically under certain loads. This requires careful engineering and design redundancies.

Difficult Recycling

CFRPs are not easily melted down like metals. Current recycling methods (like pyrolysis or solvolysis) are expensive and not yet scalable.

Environmental Impact

Producing PAN-based carbon fiber emits significant CO₂ and consumes large amounts of energy, raising sustainability concerns.

7. The Future of Carbon Fiber

The future of carbon fiber lies in scaling production, lowering costs, and enhancing sustainability.

Mass Adoption in Transportation

As electric vehicles and drones demand stronger, lighter materials, carbon fiber may become a standard component. New automation in carbon fiber layup and molding is already speeding up production.

Green Alternatives

Researchers are developing bio-based precursors like lignin (from wood pulp) and cellulose to reduce environmental impact. These could slash production costs and carbon emissions dramatically.

Recycling Innovations

Emerging techniques aim to recover both fiber and resin efficiently. Companies are experimenting with closed-loop recycling systems for industrial offcuts and end-of-life products.

3D Printing with Carbon Fiber

Combining carbon fiber with additive manufacturing is opening up new possibilities in rapid prototyping, lightweight tooling, and complex geometries.

Conclusion

Carbon fiber is a remarkable material that is reshaping industries one strand at a time. Its lightweight strength, corrosion resistance, and aesthetic appeal make it indispensable in a growing number of high-performance applications. Yet its future depends on innovation—not just in how it performs, but in how it’s made, used, and reused.

As technology continues to evolve, carbon fiber will no longer be a luxury—it will be a necessity, driving a lighter, stronger, and more sustainable future.