How Carbon Fiber is Disrupting Traditional Materials in Industrial Design

Introduction

Industrial design has always revolved around a delicate balance between form, function, and feasibility. For over a century, materials like steel, aluminum, and plastic have formed the foundation of innovation across sectors. But today, a new contender—carbon fiber—is fundamentally changing the rules of design and engineering.

With its lightweight nature, unmatched strength, and aesthetic appeal, carbon fiber is no longer limited to space shuttles and supercars. It is increasingly being used in product design, architecture, consumer electronics, and transportation. This article explores how carbon fiber is disrupting traditional materials in industrial design, what makes it so unique, and what designers need to know when integrating it into real-world applications.

1. What Makes Carbon Fiber So Disruptive?

Unrivaled Strength-to-Weight Ratio

Carbon fiber’s most celebrated feature is its incredible strength-to-weight ratio. Compared to steel, carbon fiber is:

-

5x stronger

-

2x stiffer

-

1/4 the weight

This means that designers can create structurally superior yet significantly lighter products, enabling innovations in performance, mobility, and energy efficiency.

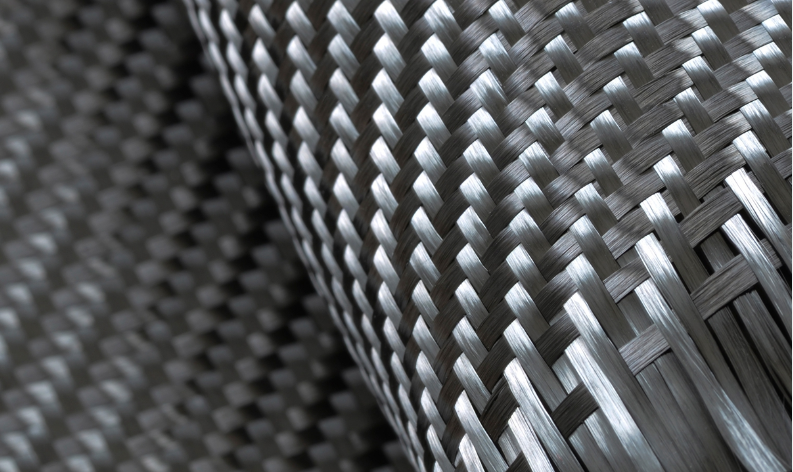

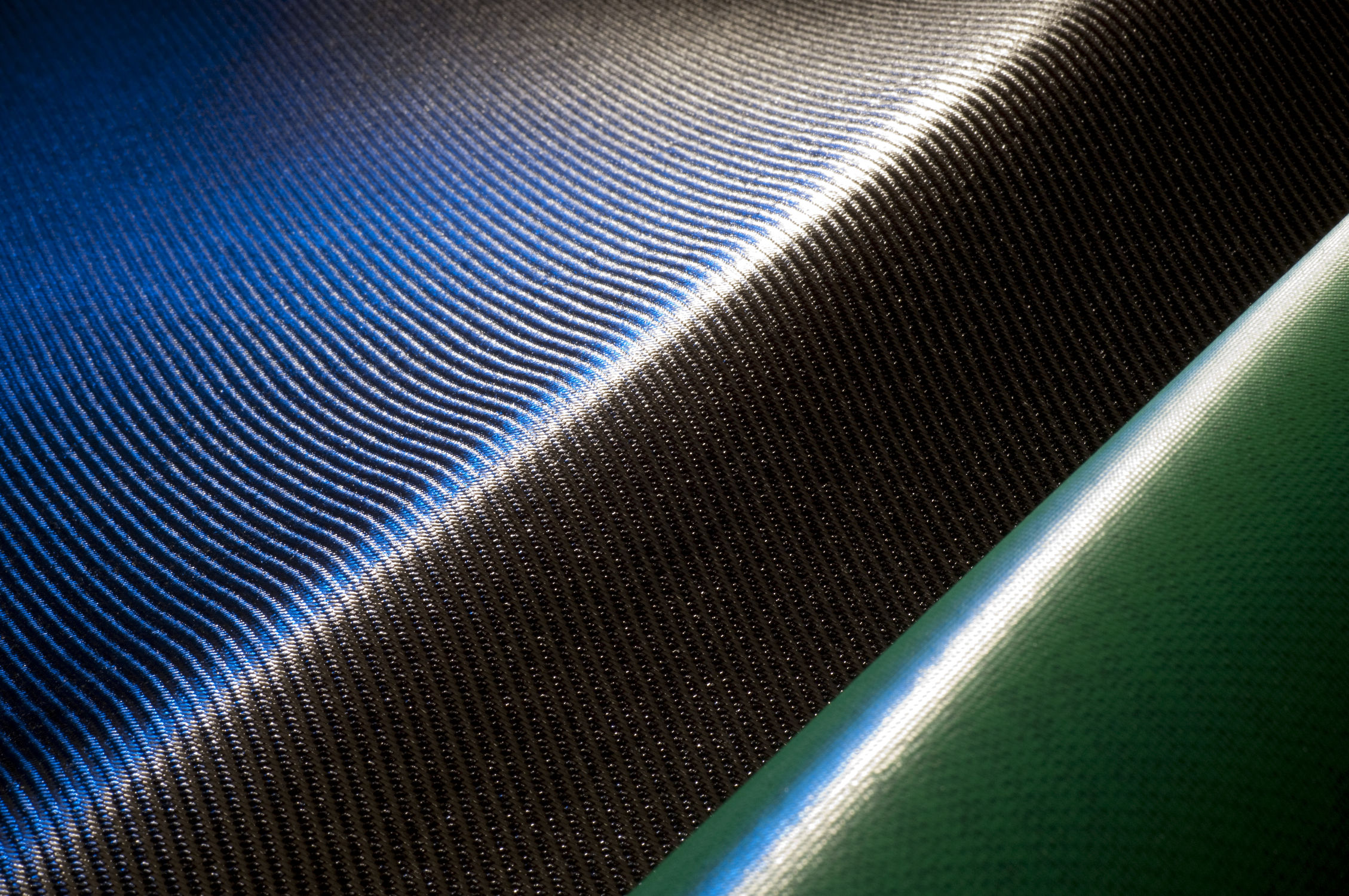

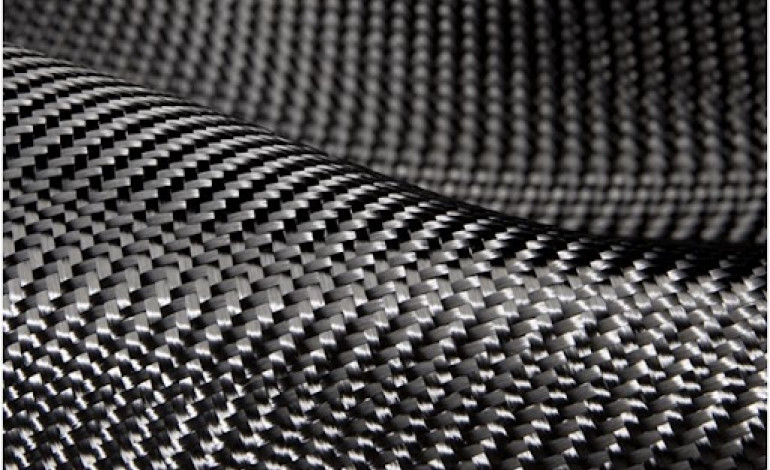

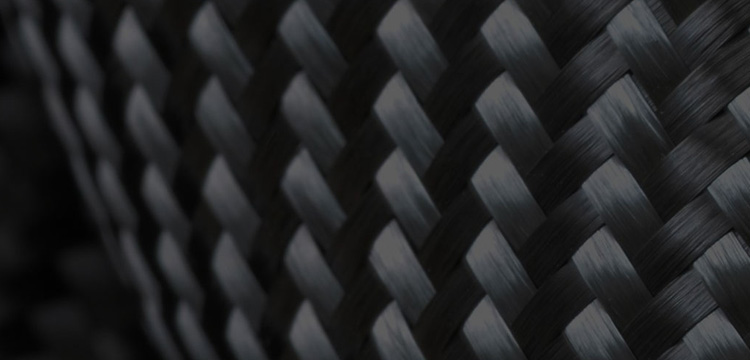

Aesthetic and Functional Minimalism

Carbon fiber has a futuristic, tech-savvy visual appeal. Its woven texture and deep-black luster have become symbols of luxury and performance. More importantly, its strength allows for minimalist designs without sacrificing durability. This is a dream come true for modern industrial designers striving for elegant, clean aesthetics.

2. Traditional Materials vs. Carbon Fiber: A Paradigm Shift

| Material | Strength | Weight | Malleability | Cost | Recyclability |

|---|---|---|---|---|---|

| Steel | High | Heavy | Moderate | Low | High |

| Aluminum | Moderate | Light | High | Low | High |

| Plastic | Low | Light | Very High | Very Low | Medium |

| Carbon Fiber | Very High | Very Light | Low | High | Low (for now) |

Carbon fiber outperforms nearly all traditional materials except in cost and recyclability. But as technologies evolve, these weaknesses are gradually being addressed, tipping the scales further in its favor.

3. Applications in Modern Industrial Design

Consumer Electronics

Carbon fiber is increasingly used in smartphones, laptops, drones, and wearables. Why?

-

It provides rigid casing without adding weight

-

It offers signal transparency (unlike metals)

-

Its texture adds a premium feel to high-end products

Example: The Lenovo ThinkPad X1 Carbon laptop leverages carbon fiber for its chassis, delivering durability with featherweight portability.

Furniture Design

High-end furniture manufacturers are experimenting with carbon fiber to create ultra-slim, high-strength chairs, tables, and shelves. These pieces not only serve a functional purpose but also act as visual statements in modern interior spaces.

Design Benefits:

-

Extreme thinness without warping

-

Long-term shape retention

-

Resistance to corrosion, heat, and UV

Bicycle & Mobility Products

In e-scooters, bicycles, skateboards, and even prosthetics, carbon fiber allows designers to:

-

Reduce frame weight

-

Enhance load-bearing capacity

-

Improve shock absorption

This leads to smoother rides, better ergonomics, and increased speed for both commuters and athletes.

Medical Device Design

Carbon fiber is radiolucent (it doesn’t show up on X-rays), making it invaluable for:

-

Surgical tables

-

X-ray equipment

-

Imaging bed frames Its sterilizability and biocompatibility also make it suitable for prosthetics, braces, and support structures.

4. Limitations Every Designer Should Know

Despite its advantages, carbon fiber presents several design challenges that must be addressed early in the development process.

Brittleness

Unlike ductile metals, carbon fiber can fail catastrophically under sudden impact or improper load distribution. Designers need to ensure:

-

Redundancy in high-stress areas

-

Proper layup orientation to handle directional forces

High Production Cost

Carbon fiber is expensive to produce, particularly in low volumes. The costs are mostly due to:

-

Raw materials (especially PAN-based fibers)

-

Energy-intensive curing and molding

-

Skilled labor and custom tooling

This means carbon fiber is still best suited for premium, low-volume products, or high-performance applications where ROI justifies the expense.

Complex Manufacturing

CFRP parts require precise layup, molding, and curing—often in autoclaves. Errors in resin distribution, fiber alignment, or curing time can lead to weak spots. This requires close collaboration between designers, engineers, and manufacturers.

5. Sustainability & Recycling: The New Frontier

One of carbon fiber’s current downsides is poor recyclability. Unlike metals, CFRPs cannot be melted down and reused easily. However, new recycling approaches are being developed:

Mechanical Recycling

Chops the material into fibers, which can be reused in non-structural applications like car interiors or tool casings.

Thermal Recycling

Uses pyrolysis to burn off resins and recover fibers—but often shortens them.

Chemical Solvolysis

Breaks down resin at low temperatures to preserve longer fibers—promising but expensive.

Bio-based Alternatives

Scientists are researching lignin- and cellulose-based precursors that could reduce environmental impact during production.

6. The Future of Carbon Fiber in Industrial Design

Cost Reduction Through Automation

Automated fiber placement (AFP) and robotic layup systems are reducing labor costs and increasing production speed, opening the door to mass-market carbon fiber applications.

3D Printing with Carbon Fiber

Additive manufacturing with carbon-reinforced thermoplastics allows rapid prototyping and production of complex parts with directional strength.

Hybrid Material Systems

Designers are blending carbon fiber with metals, foams, or recycled composites to balance strength, cost, and sustainability.

Architectural Integration

Lightweight façade systems, solar panel supports, and even tensioned bridges are beginning to incorporate carbon fiber due to its ability to handle load without requiring heavy support infrastructure.

7. Tips for Designers Working with Carbon Fiber

-

Think in terms of layers, not just shapes—fiber orientation affects strength

-

Design for the mold—complex geometries may need modular molds or pre-preg materials

-

Optimize aesthetics—carbon fiber can be left exposed, coated, or even dyed

-

Account for UV exposure—UV-resistant coatings are a must for long-term outdoor use

-

Understand your supply chain—not all carbon fibers are equal in quality, stiffness, and resin compatibility

Conclusion

Carbon fiber is not just a performance enhancer—it’s a design enabler. It offers the freedom to rethink how products are built, how they look, and how they interact with users. While cost and sustainability still present hurdles, the trajectory is clear: carbon fiber is steadily moving from the realm of the elite into the mainstream.

For industrial designers, understanding how and when to use carbon fiber is no longer optional—it’s essential. The next wave of innovation will not just be smart or connected—it will be lightweight, strong, and carbon-based.