From Labs to Lifestyle: The Rise of Carbon Fiber in Everyday Design

Introduction: A Material Born for the Stars

Carbon fiber’s story begins not on Earth, but in humanity’s dream to defy gravity. First developed in the mid-20th century, carbon fiber was created to solve one of aerospace’s greatest challenges: building something incredibly strong, yet light enough to break free from our atmosphere.

Fast forward to today, and carbon fiber has evolved far beyond the laboratories of NASA. It’s become the backbone of high-performance race cars, the secret behind featherweight bicycles, and the material of choice for minimalist furniture, sports equipment, luxury gadgets, and even prosthetic limbs.

What happened? How did a niche, elite engineering material become a lifestyle design staple? This is the story of how carbon fiber captured the imagination of designers, engineers, and creators across the world—and where it’s going next.

1. What Makes Carbon Fiber So Special?

Before diving into trends and case studies, let’s revisit what makes carbon fiber such a powerful material:

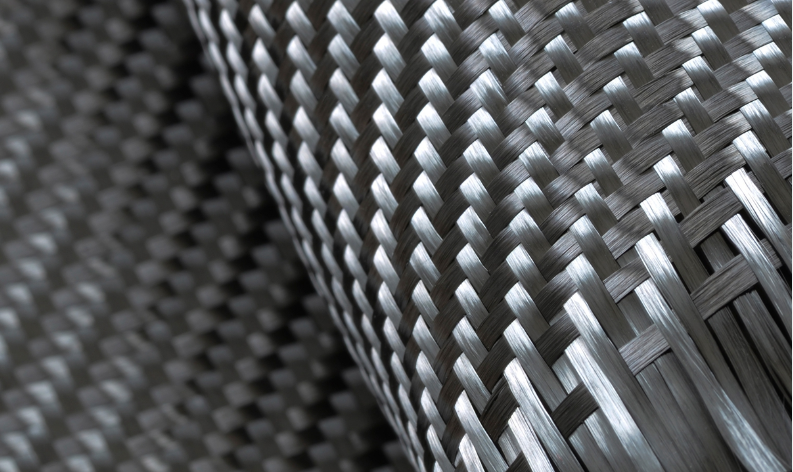

Lightweight, Yet Stronger Than Steel

-

Strength-to-weight ratio: Carbon fiber is up to five times stronger than steel but only a quarter of the weight.

-

Stiffness: It resists deformation under stress, making it ideal for load-bearing or precision components.

-

Corrosion resistance: It doesn’t rust or degrade like metals.

-

Thermal stability: It withstands heat without warping or weakening.

-

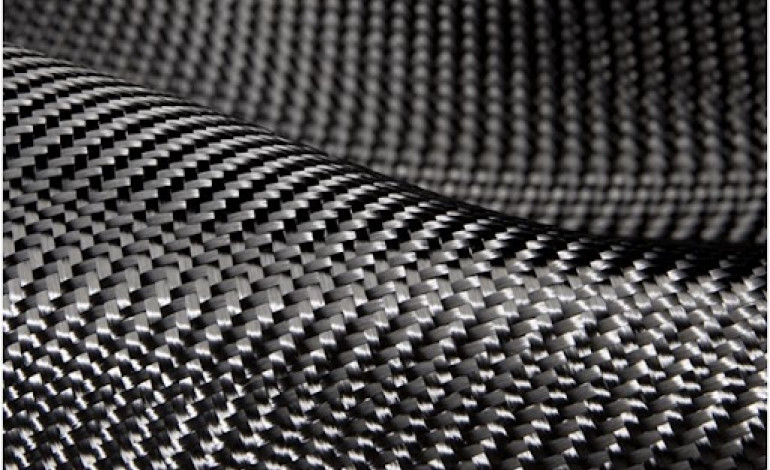

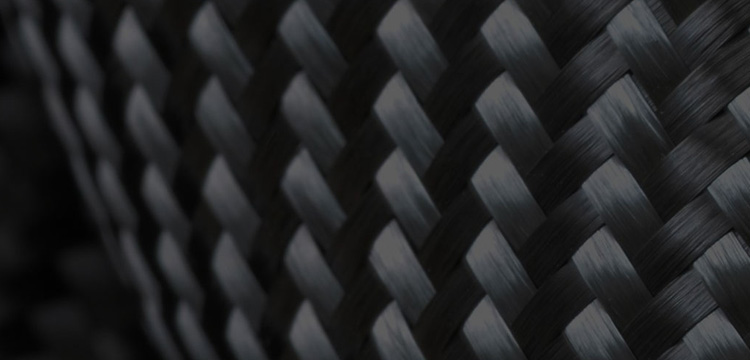

Aesthetic appeal: Its black, woven pattern is both futuristic and instantly recognizable.

This unique blend of form, function, and visual identity has made carbon fiber more than a material—it’s become a symbol of modern design thinking.

2. From Aerospace to Apple Watch: The Democratization of Carbon Fiber

Stage 1: The Elite Era

In the 1960s and 70s, carbon fiber was a material reserved for space programs, fighter jets, and Formula 1 cars. Manufacturing was expensive, processes were secretive, and availability was limited. If you saw carbon fiber, it meant performance—at any cost.

Stage 2: The Athlete’s Advantage

By the 1990s and early 2000s, carbon fiber entered the world of sports:

-

Tennis rackets and golf clubs that delivered power with less vibration.

-

Bicycle frames that shaved grams without sacrificing strength.

-

Running prosthetics, like those used by Paralympians, that mimicked spring-like motion.

Here, carbon fiber wasn’t just about function—it was about human potential. It gave athletes an edge. It pushed boundaries.

Stage 3: Lifestyle & Industrial Design

In the 2010s, something changed. As production costs began to fall and design consciousness rose, carbon fiber started appearing in unexpected places:

-

Laptop chassis (e.g., ThinkPad X1)

-

Luxury car interiors

-

Minimalist coffee tables

-

Carbon fiber wallets, phone cases, and even wedding rings

What was once ultra-high-performance became ultra-cool.

Designers now saw carbon fiber not just as a technical solution, but a creative medium—a way to express lightness, strength, and sophistication.

3. Design Case Studies: Carbon Fiber in the Wild

Carbon Fiber Prosthetics: Empowering Human Mobility

Perhaps nowhere is carbon fiber’s power more inspiring than in modern prosthetics. Designed to be springy, durable, and ultra-light, carbon-fiber limbs allow users to run, jump, and compete at world-class levels.

Designers focus not just on function, but on form—creating limbs that users are proud to show, not hide. In many ways, carbon fiber has turned prosthetics from hidden medical devices into symbols of strength and resilience.

Furniture Design: From Mass to Minimal

Carbon fiber enables ultra-thin yet sturdy structures, changing the way we approach weight-bearing surfaces:

-

A chair can weigh less than 2kg yet support over 300kg.

-

Tables can float visually, with legs that seem too slim to work.

Designers like Konstantin Grcic and brands like Vitra have used carbon composites to push the boundaries of what’s physically and visually possible in furniture.

Automotive Interiors: Where Tactility Meets Tech

Automotive designers use carbon fiber in dashboards, trim panels, and steering wheels not just to shed weight, but to create an atmosphere of precision and speed. The tactile experience of woven carbon fiber under your fingers creates an emotional connection to performance.

Even in electric vehicles, where silence replaces engine roar, carbon fiber preserves the feeling of control, agility, and motion.

4. Cultural Symbolism: Why We Love Carbon Fiber

Carbon fiber is more than a material—it’s an aesthetic and philosophical statement.

-

Weightlessness as freedom: In a world burdened by complexity and excess, carbon fiber represents minimalism, agility, and escape.

-

Strength without bulk: It’s a metaphor for modern power—quiet, efficient, and purposeful.

-

Transparency of design: The weave is usually visible, suggesting craftsmanship and openness in an age of hidden tech.

That’s why it shows up in places you wouldn’t expect—like watches, pens, and musical instruments. It’s a language of design, not just a technical tool.

5. Carbon Fiber in the Circular Economy

But this material also comes with baggage. Carbon fiber is notoriously difficult to recycle. Once the resin sets, it’s almost impossible to melt down and reform like metals or thermoplastics.

The Sustainability Challenge

-

High embodied energy: The production of PAN-based fibers and curing processes consume vast amounts of energy.

-

Landfill buildup: Many carbon fiber products end up buried after use.

Emerging Solutions

-

Mechanical shredding for short-fiber reuse

-

Chemical recycling (solvolysis) for recovering near-pristine fibers

-

Bio-based precursors like lignin and cellulose

-

Recycled fiber mats for car interiors, insulation, and non-structural uses

Sustainability is the next great design challenge for carbon fiber—and one that innovative companies are starting to tackle head-on.

6. The Future: Where Carbon Fiber Goes Next

Here’s a glimpse of where carbon fiber will likely appear next:

1. Smart Carbon Composites

Researchers are embedding sensors and circuits into carbon fiber composites, allowing them to:

-

Detect strain, cracks, or moisture

-

Transmit data wirelessly

-

React to temperature changes

This creates possibilities for self-monitoring bridges, drones, and medical devices.

2. 3D-Printed, On-Demand Carbon Fiber Products

Additive manufacturing now allows continuous carbon fiber to be printed with thermoplastics, creating structurally strong parts on demand. Expect:

-

Personalized prosthetics

-

Custom aerospace brackets

-

DIY repair tools and parts in remote areas

3. Architecture & Urban Infrastructure

Carbon fiber’s resistance to corrosion, fatigue, and weather could revolutionize how we build:

-

Modular bridges that deploy in days, not months

-

Disaster-resistant shelters that withstand extreme forces

-

Solar panel supports and wind turbine bases made lighter and longer-lasting

In urban design, carbon fiber could be a foundation of lightweight cities, where buildings are strong yet agile, built to adapt.

Conclusion: Designing Light

Carbon fiber’s journey from secret military projects to designer smartphones tells us something profound about the future of materials: the best materials are no longer just strong or cheap—they’re smart, beautiful, and versatile.

In the hands of today’s industrial designers, carbon fiber becomes more than just a means to reduce weight or increase performance. It becomes a language—one that speaks to modern values: efficiency, elegance, and sustainability.

As manufacturing advances, recycling improves, and more creators get access to carbon fiber tools, we can expect a design revolution driven not by bulk, but by lightness. Not by hiding the structure, but by revealing it. Not by force, but by flow.

The future is carbon-based—but it’s lighter than ever.