Carbon Fiber Uncovered: What It Is, How It Works, and Why It’s Changing the World

Introduction: A Material of Possibilities

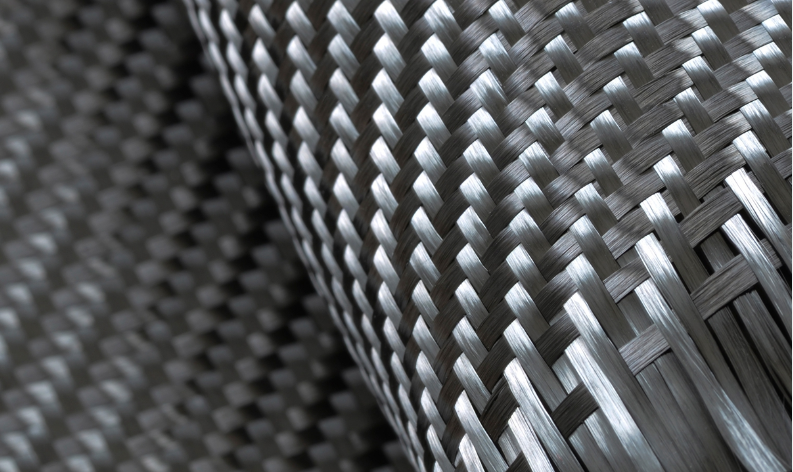

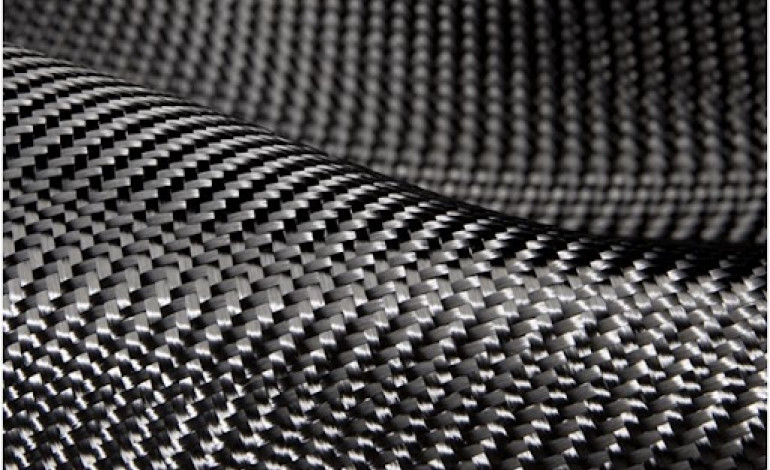

Carbon fiber has become synonymous with cutting-edge engineering and modern design. You’ve seen it in high-performance sports cars, aerospace structures, racing bicycles, and even consumer electronics. But beneath its sleek woven surface lies a world of chemistry, physics, and innovation that has revolutionized how we build, move, and design.

In this article, we’ll break down carbon fiber from the ground up—what it is, how it’s made, its key properties, and the wide range of industries it’s transforming. Whether you’re an engineer, designer, student, or just curious, you’ll leave with a deep understanding of why carbon fiber is one of the 21st century’s most exciting materials.

1. What Is Carbon Fiber?

Carbon fiber is, quite simply, a material composed of thin strands—each about 5 to 10 microns in diameter—made mostly of carbon atoms.

These fibers are:

-

Extremely strong

-

Very lightweight

-

Resistant to corrosion, chemicals, and heat

-

Often combined with resins to form carbon fiber reinforced polymers (CFRPs)

The combination of fibers (for strength) and resin (for shape and protection) makes carbon fiber composites incredibly versatile. When laid in specific orientations, these composites can outperform metals in strength, stiffness, and durability.

2. How Is Carbon Fiber Made?

The production of carbon fiber is complex and energy-intensive, but it all starts with a precursor—a material that contains carbon. The most common precursor is polyacrylonitrile (PAN), used in over 90% of carbon fiber manufacturing.

The Key Steps:

-

Spinning

The precursor is spun into long fibers. -

Stabilization

Fibers are heated in air at 200–300°C to chemically stabilize them. -

Carbonization

Stabilized fibers are heated to 1,000–2,000°C in an oxygen-free environment, driving out non-carbon atoms and leaving behind nearly pure carbon. -

Surface Treatment

The fiber surface is oxidized to improve bonding with resins. -

Sizing

A protective coating is applied to ease handling and weaving.

At the end of this process, you get high-performance carbon fibers that are ready to be woven into fabrics or layered into molds for composite parts.

3. Key Properties of Carbon Fiber

1. High Strength-to-Weight Ratio

Carbon fiber is often stronger than steel but far lighter—making it ideal for aerospace, automotive, and sports applications.

2. Stiffness

It doesn’t deform easily under stress. Engineers love carbon fiber for applications requiring precise tolerances.

3. Fatigue Resistance

Unlike metals that may wear out after repeated stress cycles, carbon fiber resists fatigue well when properly designed.

4. Corrosion and Chemical Resistance

Carbon fiber doesn’t rust, and it can withstand exposure to many chemicals, which is critical in marine and industrial environments.

5. Thermal Conductivity and Expansion

Carbon fiber has low thermal expansion, meaning it doesn’t change shape much with temperature changes—perfect for satellite components and aircraft.

4. Types of Carbon Fiber and Composites

Based on Strength and Modulus:

-

Standard Modulus (SM): Most commonly used (tensile modulus ~230 GPa)

-

Intermediate Modulus (IM): Offers a balance of strength and stiffness (~300 GPa)

-

High Modulus (HM): Very stiff (~450 GPa), used in satellites and precision tools

Based on Weave Patterns:

-

Plain Weave: Strong and stable, easy to handle

-

Twill Weave: More flexible and visually appealing (common in aesthetics)

-

Unidirectional: All fibers run in one direction, offering strength along a single axis

Common Matrix Materials:

-

Epoxy Resin: Strong and durable; the most widely used

-

Thermoplastics: More recyclable and impact-resistant

-

Vinyl Ester and Polyester Resins: Used for budget-conscious applications

5. Carbon Fiber Applications Across Industries

Aerospace

Carbon fiber reduces weight, which translates directly into fuel efficiency. Aircraft like the Boeing 787 and Airbus A350 use carbon composites for:

-

Wings

-

Fuselage panels

-

Tail structures

-

Interior components

Even satellites and space telescopes benefit from its dimensional stability in extreme conditions.

Automotive

Lightweighting is critical for fuel economy and performance. Carbon fiber is used in:

-

Body panels

-

Driveshafts

-

Wheels and rims

-

Crash structures in EVs (e.g., battery casings)

Luxury brands like McLaren, Porsche, and BMW have pioneered carbon monocoque frames for safety and stiffness.

Sports and Recreation

Carbon fiber enhances performance in everything from:

-

Racing bikes and tennis rackets

-

Skis and snowboards

-

Fishing rods and archery bows

-

Rowing shells and kayak paddles

Its vibration-damping and strength characteristics improve user comfort and control.

Construction and Infrastructure

In civil engineering, carbon fiber is used for:

-

Bridge retrofits

-

Earthquake-resistant structures

-

Strengthening concrete beams and columns

It’s valued for its long-term durability and non-corrosive properties.

Consumer Electronics

From laptops to headphones and smartphones, carbon fiber is used for:

-

Structural frames

-

Aesthetic finishes

-

Drop resistance and thermal control

It offers a modern, technical look while adding functional durability.

6. Challenges and Limitations

Despite its advantages, carbon fiber has some drawbacks:

1. High Cost

Carbon fiber remains significantly more expensive than aluminum or steel, though costs are gradually dropping.

2. Manufacturing Complexity

Production requires specialized equipment and skills. Repairing damaged carbon composites is also difficult.

3. Environmental Concerns

-

High energy consumption during production

-

Limited recycling infrastructure

-

Difficulty reusing long continuous fibers

Researchers are now exploring bio-based precursors and new recycling technologies to reduce environmental impact.

7. The Future of Carbon Fiber: Trends to Watch

1. Mass Adoption in EVs

Electric vehicle makers are investing in carbon fiber to reduce battery weight and improve safety. Expect wider adoption in mid-tier vehicles as manufacturing scales.

2. Sustainable Carbon Fiber

New sources like lignin (a waste byproduct from paper mills) could offer low-cost, low-emission alternatives to PAN-based carbon fiber.

3. Smart Carbon Composites

Embedded sensors in carbon fiber structures could help detect damage, monitor performance, or even trigger repairs.

4. 3D-Printed Carbon Composites

Additive manufacturing is enabling the custom fabrication of carbon-reinforced parts for aerospace, tooling, and medical implants.

5. Architectural Innovation

Look for carbon fiber in futuristic building designs, modular bridges, and kinetic structures that adapt to weather or movement.

8. Should You Use Carbon Fiber? A Decision Guide

If you’re a designer, engineer, or entrepreneur, carbon fiber might be a powerful material choice for your next project. Here’s when it makes sense:

You need the lightest possible part

Your structure requires high stiffness and strength

The part will be used in corrosive or high-stress environments

You’re building something that benefits from a tech-forward, premium aesthetic

But carbon fiber might not be right if:

You’re on a tight budget with high production volume

The part needs to flex or absorb energy (metals are better here)

You lack access to experienced composite fabricators

Conclusion: The Carbon Fiber Era Has Just Begun

Carbon fiber is more than a high-tech material—it’s a catalyst for better, smarter, lighter design. Its emergence across industries proves that the future of engineering won’t be made from the heaviest or cheapest materials, but from those that deliver more performance with less weight, less waste, and less compromise.

As production becomes cleaner, costs drop, and recycling improves, carbon fiber is set to leave its niche status behind and reshape how we build everything from skyscrapers to sneakers.

We’re only just beginning to unlock its potential.

Welcome to the carbon fiber era.