Carbon Fiber: The Future of Manufacturing and Innovation

Introduction: The Power of Carbon Fiber

Carbon fiber is arguably one of the most transformative materials of the modern age. Lightweight, strong, durable, and resistant to corrosion, carbon fiber offers unparalleled possibilities across a wide range of industries. From aviation to automotive design, from sports equipment to luxury products, carbon fiber is revolutionizing the way we think about design, manufacturing, and engineering.

But despite its remarkable properties, carbon fiber is still relatively expensive to produce. This has limited its widespread adoption in many industries. However, the future is promising. Advancements in manufacturing technologies, sustainability efforts, and material science could lower production costs, making carbon fiber accessible to a broader range of industries. In this article, we will explore the current state of carbon fiber, how it’s being used today, and what the future holds for this powerful material.

1. The Basics of Carbon Fiber: Why It’s So Unique

Before we dive into the future of carbon fiber, it’s important to understand the fundamentals of what makes this material so unique.

What Is Carbon Fiber?

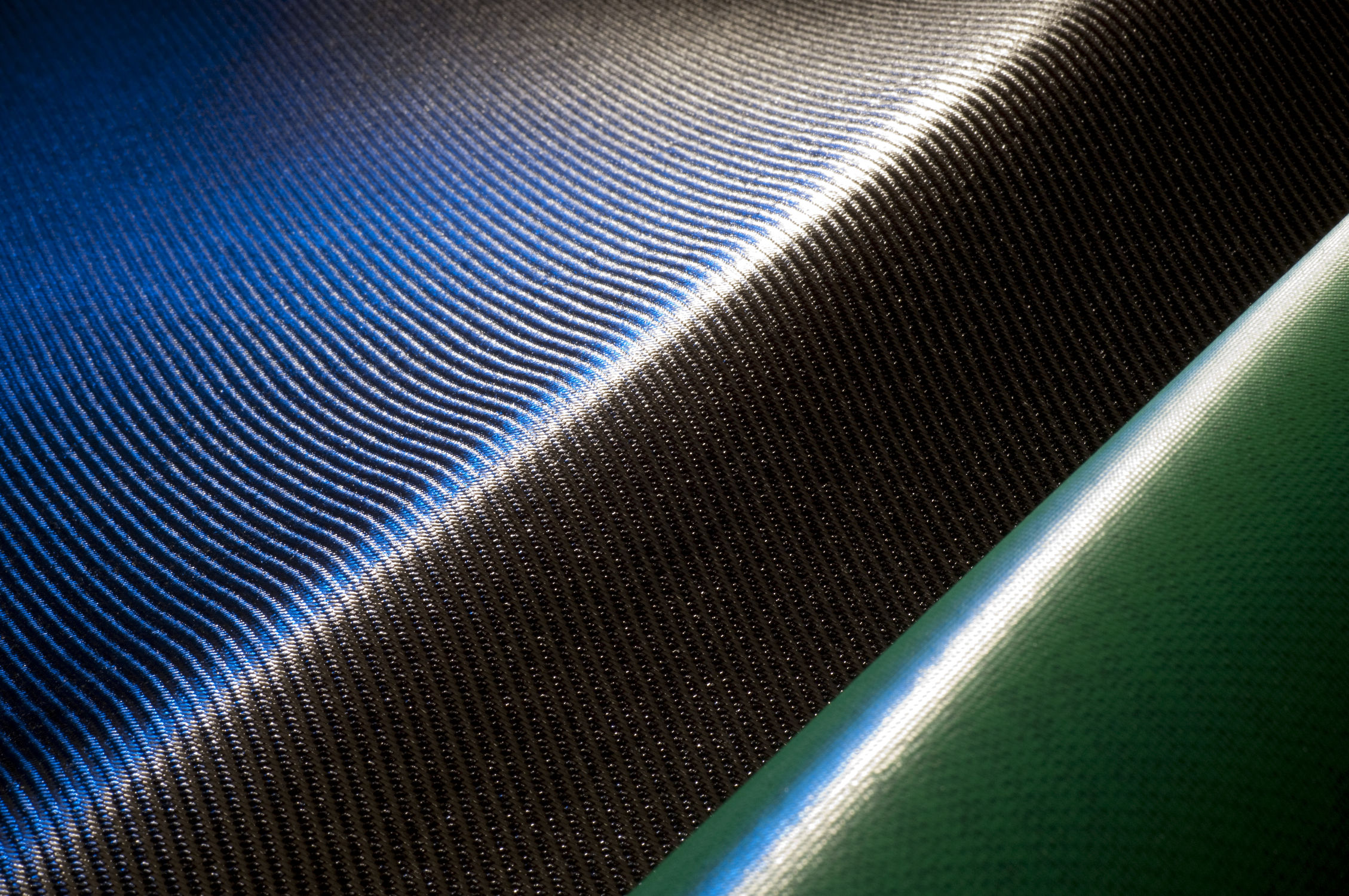

Carbon fiber is a polymer made up of carbon atoms bonded together in a crystalline structure. The fibers themselves are typically 5 to 10 microns in diameter—roughly the width of a human hair—and are made through a complex process known as carbonization. This involves heating organic precursor fibers (often polyacrylonitrile (PAN)) to extremely high temperatures (1,000°C to 2,000°C) in a controlled, oxygen-free environment, which forces out most non-carbon atoms, leaving behind pure carbon.

Key Properties of Carbon Fiber

The unique properties of carbon fiber make it incredibly desirable for a wide range of applications:

-

High Strength-to-Weight Ratio: Carbon fiber is stronger than steel but much lighter, making it ideal for applications where reducing weight is crucial, such as in aerospace and automotive engineering.

-

Stiffness: Carbon fiber composites are much stiffer than traditional materials, offering superior resistance to bending and deformation.

-

Corrosion Resistance: Unlike metals, carbon fiber doesn’t corrode or rust, making it ideal for use in harsh environmental conditions, such as marine environments or extreme temperatures.

-

Fatigue Resistance: Carbon fiber structures tend to withstand repetitive stresses over time, making it highly durable in high-performance applications.

-

Design Flexibility: Carbon fiber is extremely versatile. It can be molded into virtually any shape and woven into various patterns to meet different performance and aesthetic requirements.

2. The Manufacturing Challenges of Carbon Fiber

While carbon fiber is an incredibly versatile and powerful material, its production comes with its own set of challenges. Understanding these challenges is essential for predicting the future of carbon fiber and the industry’s ability to scale its use.

Expensive Production Process

The manufacturing of carbon fiber involves high costs due to the energy-intensive process required to produce it. The precursor material—polyacrylonitrile (PAN)—must be carefully processed to produce the final carbon fiber, and the entire process requires specialized machinery, a controlled environment, and high temperatures. In addition, the carbon fiber manufacturing process currently requires a high amount of manual labor for tasks like weaving, molding, and curing.

This high cost is one of the reasons carbon fiber remains largely reserved for premium products like aircraft or Formula 1 cars. The expense associated with production means carbon fiber hasn’t yet found widespread use in lower-cost products.

Limited Recycling Options

Recycling carbon fiber is also a challenge. Unlike metals like steel and aluminum, which can be melted down and reused, carbon fiber composites don’t lend themselves to traditional recycling methods. This creates waste, as most carbon fiber products end up in landfills at the end of their life cycle.

However, innovative solutions are emerging. Researchers are experimenting with chemical recycling methods that break down carbon fiber composites back into their original fibers, enabling reuse. These methods could dramatically reduce the environmental impact of carbon fiber production, making it a more sustainable material in the future.

3. Carbon Fiber in the Present: What Are We Using It For Today?

Despite the challenges of manufacturing and recycling, carbon fiber has already found applications in a variety of industries. From aerospace to sports, carbon fiber is used in high-performance products that demand the material’s extraordinary properties.

Aerospace and Aviation

One of the most well-known and longstanding uses of carbon fiber is in the aerospace industry. Carbon fiber is used extensively in aircraft structures, including fuselages, wings, and interior components. Its strength-to-weight ratio makes it ideal for reducing the overall weight of aircraft, improving fuel efficiency, and increasing payload capacity.

For example, the Boeing 787 Dreamliner and the Airbus A350 both use carbon fiber composites in their construction to reduce weight and improve fuel economy. In the future, we may see even more widespread use of carbon fiber in next-generation commercial and military aircraft, as well as in space exploration technologies.

Automotive Industry

In the automotive industry, carbon fiber is used in high-performance vehicles, particularly in the luxury and sports car sectors. Car manufacturers like McLaren, Porsche, and BMW have used carbon fiber in key components such as body panels, wheels, and structural elements. Carbon fiber allows for lightweight design without compromising strength or safety.

For electric vehicles (EVs), carbon fiber’s potential is immense. Reducing the weight of an EV can significantly improve its energy efficiency, thus extending battery life. With the rise of EVs, carbon fiber could become more common in the automotive industry, especially as manufacturers look to make electric cars lighter and more efficient.

Sports and Recreation

In the world of sports equipment, carbon fiber has become the material of choice for many products that require a combination of light weight and high strength. Bicycles, tennis rackets, fishing rods, skis, and snowboards are just a few examples of sports equipment that rely on carbon fiber for its superior performance.

The popularity of carbon fiber sports equipment has grown as athletes have become more focused on maximizing their performance and minimizing weight. Whether it’s a racing bike frame or a professional golf club, carbon fiber allows for designs that push the boundaries of speed, agility, and durability.

Consumer Goods

Over the past decade, carbon fiber has also found its way into consumer electronics and fashion accessories. Smartphones, laptops, and watches are being made lighter and more durable thanks to the use of carbon fiber in their construction. Carbon fiber phone cases, wallets, bags, and wedding rings are now available in the consumer market, giving individuals the opportunity to own luxury, durable products made from this high-performance material.

4. The Future of Carbon Fiber: Innovation and Trends

While carbon fiber has already established itself in a variety of industries, the future is even more exciting. Advances in manufacturing technologies, sustainability efforts, and material innovation will help push the material into new industries and applications.

1. Lower Costs and Mass Adoption

The biggest challenge for carbon fiber’s widespread adoption is its cost. However, efforts are being made to bring down the price. As manufacturing processes improve and become more automated, the cost of carbon fiber will likely decrease, making it more affordable for industries beyond aerospace, automotive, and sports.

Innovations in tape-laying technology, 3D printing, and direct carbon fiber 3D printing could lower production costs even further, making carbon fiber accessible for a wider range of applications. This could open the door for new uses in industries like consumer electronics and construction.

2. Carbon Fiber Recycling

As mentioned earlier, carbon fiber’s recycling challenges are one of the material’s most significant hurdles. However, recycling technologies are advancing rapidly. By developing better ways to reclaim and reuse carbon fiber, manufacturers can reduce waste and make carbon fiber a more sustainable option.

Chemical recycling methods and closed-loop systems are becoming more refined, enabling carbon fiber to be reused without degrading its properties. This could make carbon fiber a more eco-friendly material in the future.

3. Smart Carbon Fiber: Embedded Sensors and IoT Integration

One of the most exciting innovations on the horizon is the development of smart carbon fiber composites. By embedding sensors into carbon fiber materials, engineers can create structures that “talk back” by monitoring their own condition. These smart materials can detect stress, cracks, or temperature changes, providing valuable real-time data for maintenance, repair, or performance optimization.

The integration of Internet of Things (IoT) technologies could transform how carbon fiber is used in industries like construction, automotive design, and aerospace by enabling predictive maintenance and smarter designs.

Conclusion: A Material for the Future

Carbon fiber is more than just a high-tech material—it’s a game-changer that will continue to shape the future of manufacturing and innovation. With its unique combination of strength, lightness, and versatility, carbon fiber offers endless possibilities for industries looking to improve efficiency, performance, and sustainability.

As new manufacturing technologies, recycling methods, and design possibilities emerge, carbon fiber will undoubtedly become an even more integral part of our world. The material’s potential is vast, and we’re only just beginning to scratch the surface of what it can achieve.

The future of carbon fiber is bright, and it’s only a matter of time before it becomes a fundamental material for a new era of manufacturing and design.